Below is just an extract of some of the services available in our catalogue. There are a lot more. Please contact us for more information.

Conducting comprehensive safety assessments of Service Robots by evaluating the safety mechanisms, emergency protocols, and potential hazard detection of the robots to ensure they meet necessary standards and provide a safe interaction environment for users

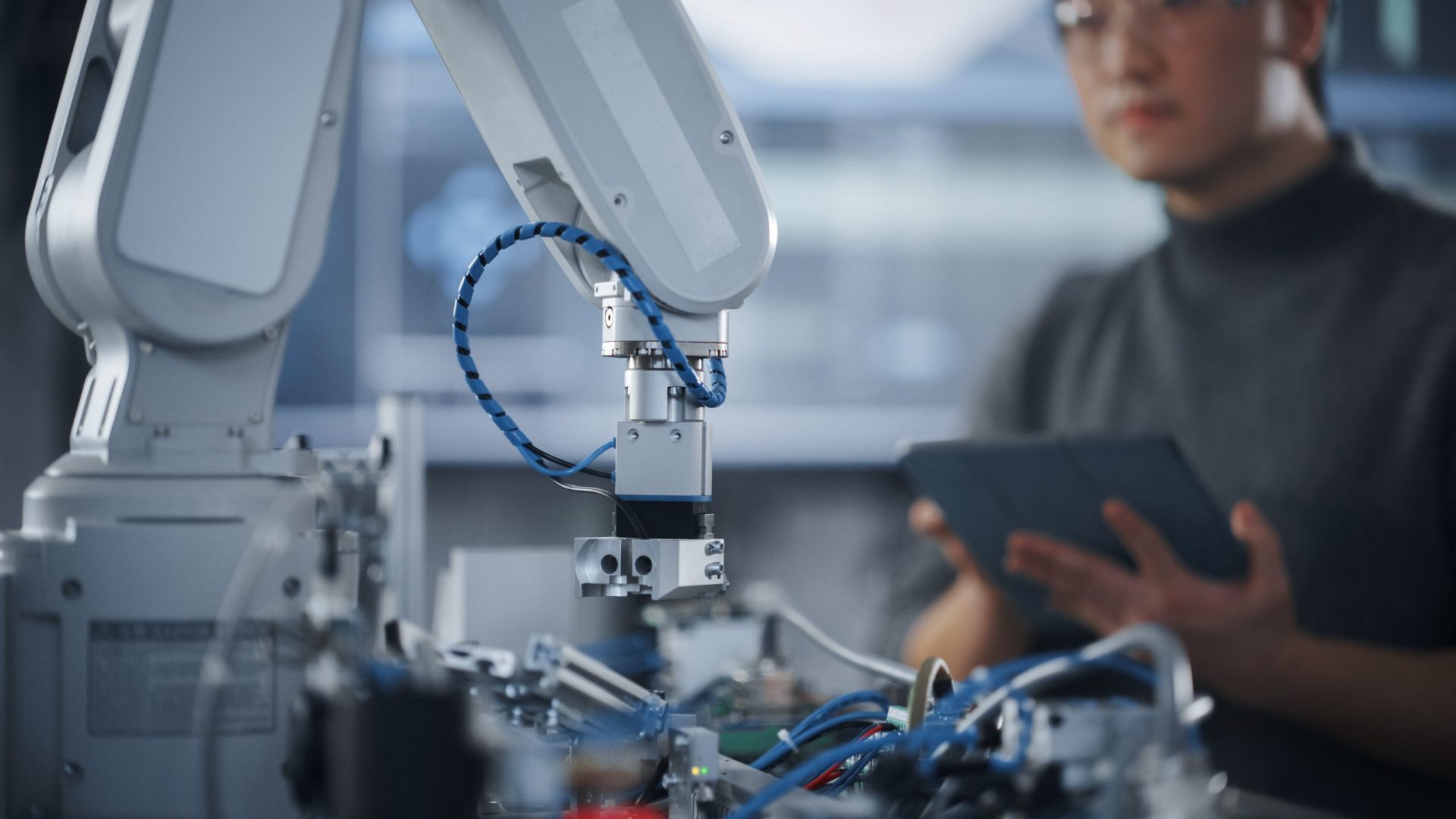

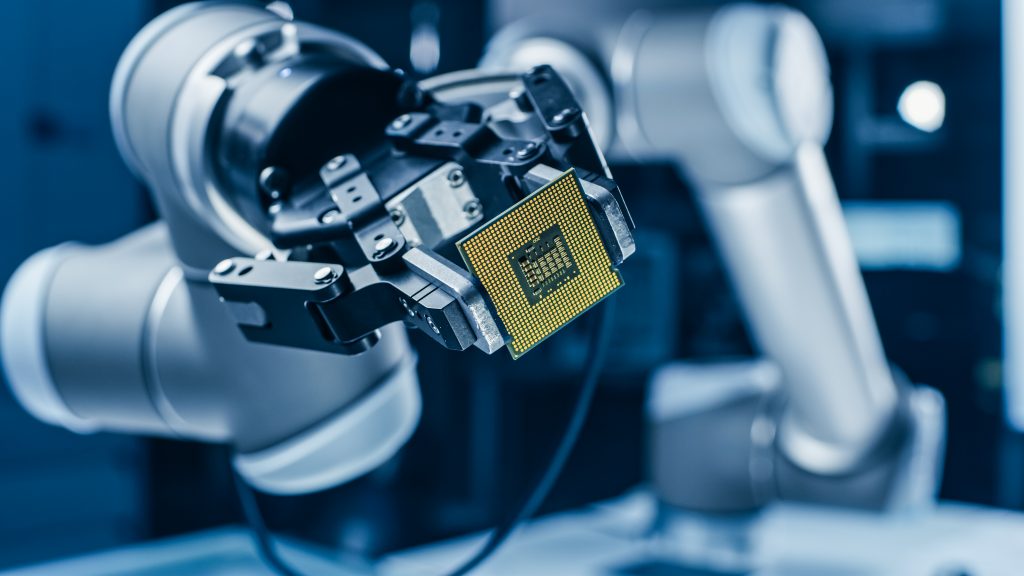

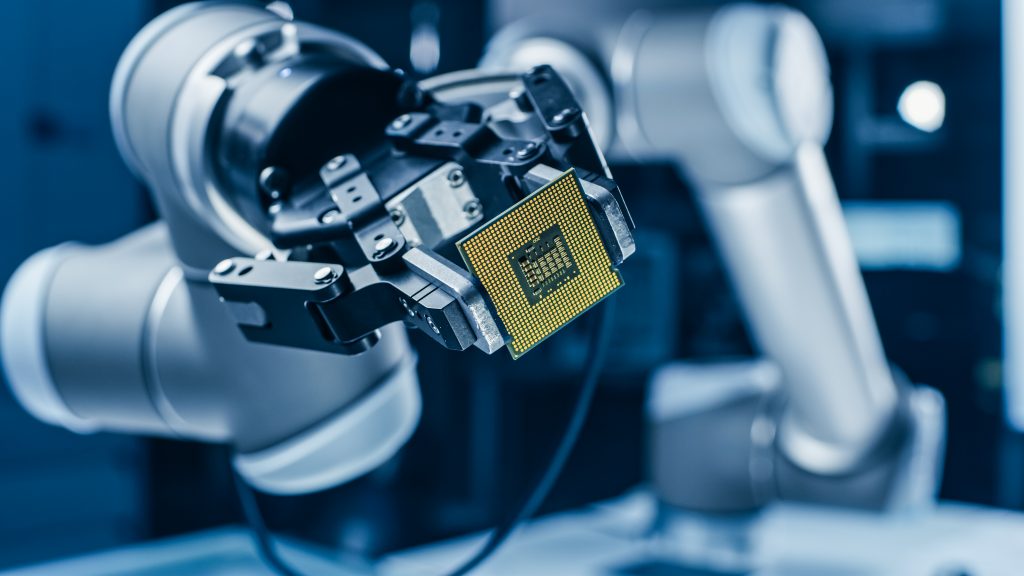

Evaluating the feasibility and potential impact of integrating mobile robots into customer’s existing facilities. Leveraging our in-house expertise, we assess the site-specific requirements, operational efficiency, and potential enhancements to the workflow that can be achieved

Systematic selection and evaluation of suitable sensors, such as 2D/3D Lidar, GPS, IMU, radar, ultrasonic, and cameras for Service Robots. The goal is to assess the performance, cost-effectiveness, and compatibility of these sensors, ensuring optimal

Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the Directorate-General for Communications Networks, Content and Technology. Neither the European Union nor the granting authority can be held responsible for them.

© copyright 2024 AI-Matters

© copyright 2024 AI-Matters