Below is just an extract of some of the services available in our catalogue. There are a lot more. Please contact us for more information.

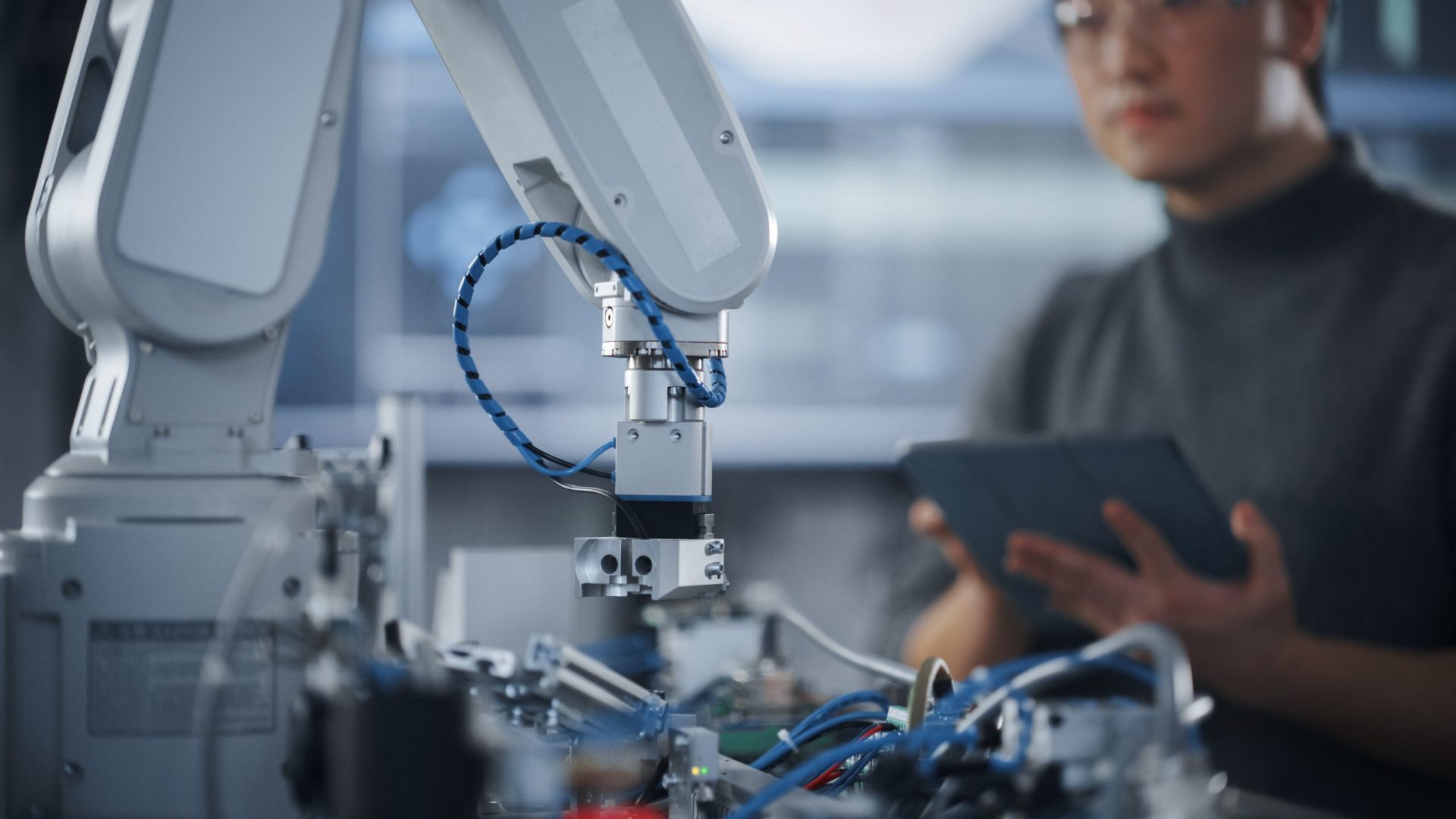

This service enables the experimentation with AI in the context of safety management and flexible prorduction systems with the use of Augmented Reality (AR)/Virtual Reality (VR) tools for Human robot collaboration. AI empowered algorithms for

Experimentation with the concept of training machine vision solutions with the use of synthetic training data. A set of reference parts will be used to train your machine vision solution. The result of the service

This service is offered for the testing and experimentation on AI-enabled algorithms for layout optimization. The capabilities and potential of virtual reality simulation for intuitive and multi-stakeholder engagement can be exploited for the comprehensive and

This service provides an industrial testbed for research and experimentation. With the aid of this service, engineers and researchers can set up Internet of Things sensors, gather and process data instantly, and view operational metrics

Dynamic Robot Task Planning & Resources Orchestration service focuses on optimizing robot task execution in dynamic environments. Within this service it is possible to experiment with the potential of AI to enable robots to adapt

This service is dedicated to the testing and experimenetation with AI tools enabling intuitive and ad hoc robot programming. A diverse set of collaborative robotic cells, including low payload, high payload, and mobile robots, offer

High-frequency and high-accuracy measurements can help to understand flexibibity/modeshapes of flexible products, or help to understand dynamic behaviour of products in a pile or on a moving conveyor belt.

To minimize time spent in programming how to perform a task, the user can teach the robot by demonstration. This can be done by first stearing the robot by hand, while monitoring its state. Eventually

Experiment with one or two Panda cobots to investigate if they can add value in the production line. A single arm could be utilized for product singulation, e.g. in a bin- or heap picking task.

Experiment with mobile platforms that might be used in a manufacturing hall to get products from point A to B across the shop floor.

Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the Directorate-General for Communications Networks, Content and Technology. Neither the European Union nor the granting authority can be held responsible for them.

© copyright 2024 AI-Matters

© copyright 2024 AI-Matters